The ability to solve problems, the thirty years of experience in understanding and optimizing processes according to customer’s requests, make the company a real reference point for its customers.

MGT is able to supply finished products, from raw materials, up to the heat and surface treatments, with the help of certified partners.

After the chip removal phases and possible treatments, the products are subjected to dimensional checks and when required, they are washed with dedicated protective.

Quality

All the processes carried out in MGT are monitored through manufacturing cycles and strict controls during both phases of realization that in the final stages of the production process.

The quality control is performed in the measuring room at a constant temperature, equipped with certified equipment such as automatic three-dimensional machine, profilometer, endoscope, profile projector and precision instruments subject to periodic calibration.

cleaning

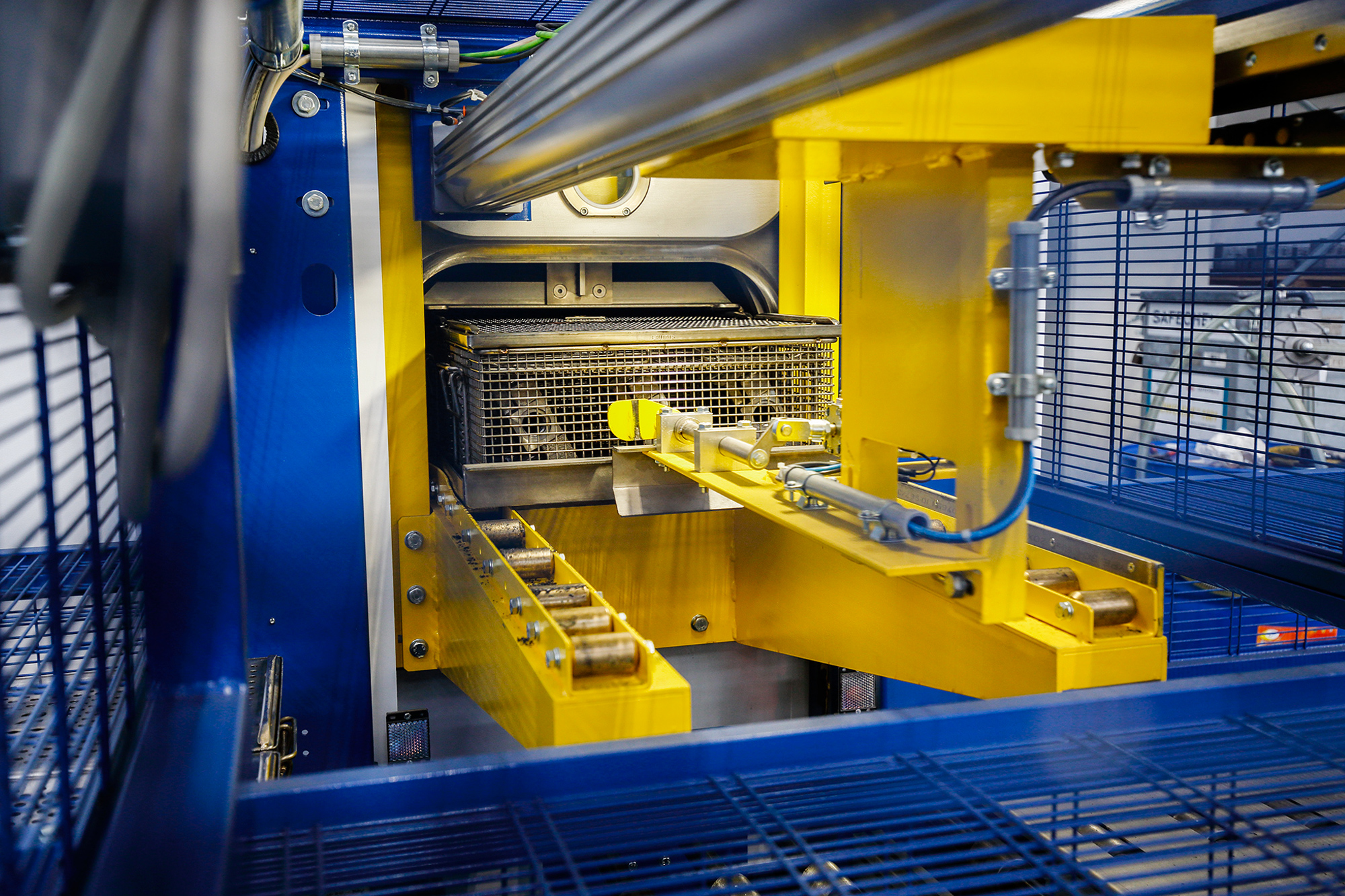

Our meticulous manufacturing process includes the important step of washing.

MGT is equipped with the best technology on the market: thanks the washing cycle with modified alcohol, in vacuum conditions, we ensure that, at the end of treatment, no residue of the solvent is present on the components or released into the environment.

Our washing machine guarantees the best results in washing metals, whatever the degree of contamination and the type of the particular is, even in case of blind and / or deep drilling.